At the beginning of the 20th century, Chinese citizens began to use electrical appliances on a large scale. It can be said that electrical appliances have become a very common kind of thing. Although the generalization of electrical appliances has brought us many conveniences, it has also brought us Dangerous. In recent years, more and more news broke, and electrical appliances caused explosions due to poor heat dissipation during use. Such news abounds, so today's article we take LED lights as an example. Custom LED heat sink supplier china will tell you about the heat dissipation of electrical appliances!

1. Like all electronic parts, LEDs will generate thermal energy and temperature rise during use or operation. If the heat dissipation problem is ignored, the LED will be burned out due to high temperature.

2. Due to the development of high-power LED technology, LED luminaires face the severe challenges of thermal management and heat dissipation design, because an increase in temperature will not only cause the brightness to decrease, but also accelerate the luminaire body and packaging materials when the temperature exceeds 100 degrees Celsius. Degradation. Therefore, in addition to the heat dissipation technology of the LED package itself, the heat sink of the LED lamp is the biggest key to maintaining the life of the lamp.

The poor heat resistance of LED lamps is well known, and it will inevitably bring about the problem of the life of the wick. However, the plastic material is very passive in heat dissipation, and it is mostly air-cooled or even closed. Like some lamps, a plastic sleeve is added between the driver board and the aluminum heat sink to increase the reliability of the insulation, and it is also necessary to fill the heat sink with silica gel to improve the heat dissipation ability. Generally, the internal temperature of this type of lamp will be 70 to 80 degrees. And if both heat dissipation and weight are taken into consideration, it is difficult to ensure heat dissipation due to both weight and weight, which is a difficult choice in this existing design. And the price of plastic will be too expensive, so plastic is not suitable for LED lights.

Custom Led Heat Sink Supplier China

Aluminum alloy is recognized as a good heat dissipation material in the manufacture of LED lamps. On the one hand is its good heat dissipation coefficient, on the other hand is its price. Aluminum alloy has good thermal conductivity, which can help LED lights to dissipate heat. And the aluminum alloy material has the characteristics of light weight, which is convenient for installation and handling. When the heat dissipation is the same, its weight is only one eleventh of the cast iron radiator, one sixth of the steel radiator, and one third of the copper radiator.

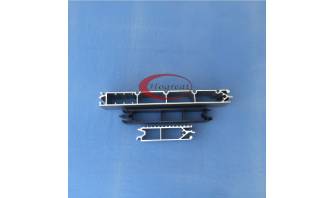

Extrusion aluminum profile heat sinks can be used for various surface treatments, with a wide variety of designs, no solder joints, strong decoration, beautiful and durable, and can meet people's individual requirements. Zhigao Industry will also draw, electroplating, anodizing, radium carving, baking paint and other processes to produce LED radiators that meet public aesthetics.

Based on the above comparison, I believe everyone has a certain grasp of choosing LED heat sinks. Zhigao Industrial is mainly specialized in processing aluminum profile automotive power amplifier radiators, aluminum profile home audio radiators and aluminum profile LED radiators. It also handles CNC processing and manufactures various aluminum materials and hardware accessories.