Aluminum is an extremely versatile metal in that it is a terrific candidate for a large range of producing techniques, 2 of which are extrusion as well as spreading. You might find yourself asking, "What is the distinction between extruding and also casting of aluminum?" Extrusion is a process by which aluminum billets are required through a die, leading to a wanted sample. Whereas, casting is a process in which molten aluminum is poured into a mold and mildew and then allowed to solidify.

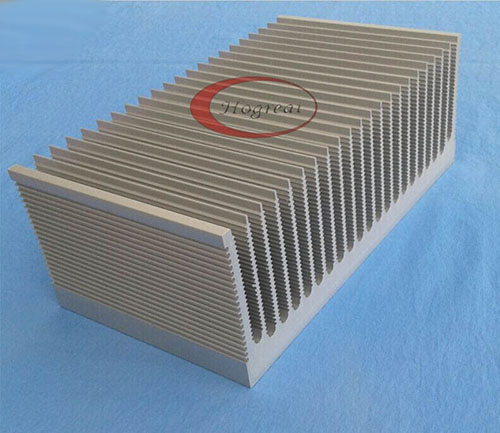

Extruded Aluminum Profiles is a normally affordable as well as affordable production choice, especially when handling really complicated cross-sections. New aluminum extrusions can be generated in just 6 weeks. Such forms as attributes that can be extruded are press as well as snap, sliding fits, tongue as well as groove, self-tapping screw holes, hinges, snap-fit joints, flanges, screw ports, anti-skid surfaces, and a lot, much more. Preliminary expenses of extrusions are eye-catching as well. Pass away engineering charges for new custom forms are a lot less than when contrasted to spreadings. Extruded aluminum forms are likewise created with a superb surface area finish as well as are usually more powerful in contrast. Some items produced by the extrusion process are warm sinks, window and door structures, manifolds, and lighting track devices. A negative aspect of extrusion, when contrasted to spreading, is the size restriction. Aluminum extrusions are restricted by the size of both the billet and also the capability of the cylindrical tube on the extrusion press. Castings have no such restriction as well as are typically made use of to create very large things. Despite the dimension limitations of extrusions, there is still a myriad of applications of which this technique of manufacture is the premium option.

Aluminum can be cast utilizing any one of the available spreading methods. Some of these casting methods are constant spreading, investment spreading, plaster casting, sand spreading, long-term mold casting, and also die spreading. Extra spreading procedures such as hot and also isostatic pushing, squeeze spreading, and also lost foam are additionally possible with molten aluminum. Despite the various names and approaches, all spreading has one point alike: Molten aluminum is poured into a mold that makes a pattern when the aluminum is cooled. When compared to extrusion, spreading is a much slower procedure. Seams and also mold blemishes can likewise be present in cast parts. This commonly calls for a second process, referred to as fettling, to be essential to remove such imperfections by cutting, grinding, or sanding. Nevertheless, casting still has its place in production. The casting of aluminum is an extremely usual production approach of such products as kitchenware, small home appliance components, or decorative components. The most common and also largest market for aluminum spreadings remains in the vehicle market. Over half of the aluminum made use of in cars and trucks is created by casting.

The process of casting often has a greater introductory expense than when compared to that of extrusion. Nonetheless, it can be more economical in high manufacturing runs or on parts that need outstanding dimensional precision. This particularly applies when the forms are detailed, such as those with non-uniform thicknesses. Though a spreading may generate closer tolerances, an extruded form will be stronger. Also, a spreading is likely to include even more porosity while an extrusion commonly has a much better surface finish. Spreadings are restricted to steels with reduced melting points, such as aluminum, magnesium, and copper, have higher preliminary tooling expenses, and also mold and mildew life can be short. Extrusions are a better option in much shorter manufacturing runs due to lower start-up prices. Castings, unlike extrusions, are not constrained by dimensions. Since an extrusion can only be as huge as the billet the extrusion press can include, the size range is limited. This is not the cast with molds for castings. As a matter of fact, spreadings are really typically made use of to produce big components, such as watercraft props or parts of engines. For these items, extrusions are not an alternative as a result of the dimension restraint. Whether taking into consideration a casting to extrusion, it is essential to take into consideration all variables of each.

Our team is ready to tackle any type of aluminum demand. For all of your Aluminum Profile requirements, request a complimentary quote on our internet site.