The creation of a conservation-oriented society has become a consensus, but the overall efficiency of high-pressure sodium lamps still heavily used in factory lighting is not high, only about 70%, and the color rendering index is low. The nighttime lighting feels dim, which is not good for factory work Personnel's discrimination of product operations has a certain impact on the safety of factory processing operations. LED street light heat sink supplier share with you:

At present, high-power white LEDs are unique in terms of luminous efficiency (> 80lmPW), service life (> 50,000 hours), light output characteristics, color rendering performance (75-80), color temperature selection, controllability, and green pollution-free. Advantages, according to the requirements of factory lighting design standards, convenient and flexible design of satisfactory factory lighting fixtures that meet the light output requirements, and become a highly competitive new high-quality light source. Among several key technologies that determine the application of LED factory lighting, heat dissipation design is a very important part, and it is also one of the technical bottlenecks that restricts its widespread use. In other words, the quality of the heat dissipation design will directly determine the performance indicators of the LED factory lighting, and whether the actual promotion and application can be successful.

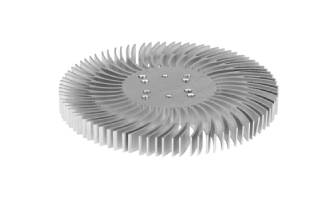

Custom Led Heat Sink

1. Aluminum extrusion LED heat sink

The physical size of the large chip is 1 ~ 6125mm2, the area is small, the power density and heat generation are large, 80% ~ 85% of the consumed power will be converted into thermal energy and needs to be dissipated, and the temperature of the chip exceeds a certain value As the light emission wavelength becomes longer and the color shifts red, there will be many problems, such as a decrease in the light output efficiency and a decrease in the service life of the chip. Therefore, to ensure that high-power LEDs can be used normally and effectively, a custom led heat sink is the key problem that needs to be solved first.

Second, the impact of temperature on the LED and a package heat dissipation scheme

The relationship between the junction temperature and the luminous flux and service life of high-power LED chips is extremely close. In order to dissipate up to 80% to 85% of the heat, the LED adopts a scientific thermal process design and a fruitful packaging process when packaging. By applying a highly thermally conductive material (internal heat sink) to ensure that the high heat generated by the chip can be smoothly exported, the LED after packaging and molding has good thermal conductivity and heat dissipation performance.

Third, the relationship between LED junction temperature and luminous flux, life

Based on the working characteristics of high-power LEDs, the junction temperature is directly related to the amount of luminous flux and the length of the service life.

As the junction temperature of the LED chip rises, the luminous flux outputted by it decreases regularly, and the service life also shows a rapid decline. Therefore, trying to maintain the temperature of the chip within the allowable range is a key technical problem that LED applications must first solve.