Led round aluminum radiator suppliers made a simple comparison of some physical properties of pure copper and pure aluminum:

Everyone thinks that the thermal conductivity of copper is strong because the thermal conductivity of copper is much higher than that of aluminum (here referred to as pure copper and pure aluminum). This is indeed what I have learned in high school. However, the heat dissipation capacity of a radiator is not only related to the thermal conductivity of the material but also related to the heat dissipation area, the shape of the radiator, and the airflow.

Looking at the last two parameters, if you just look at the specific heat capacity, you will definitely say, wow, copper has a smaller specific heat capacity, its temperature rises faster, and it is not easier to dissipate heat (law of thermodynamics, the greater the temperature gradient, the greater the heat transfer) The faster), it seems right, but... you have to look at their density.

The density of copper is 3.3 times that of aluminum. The heat sink is a size-oriented product and cannot be enlarged indefinitely. In the same volume, is the heat capacity of copper or aluminum small? Let's simply calculate.

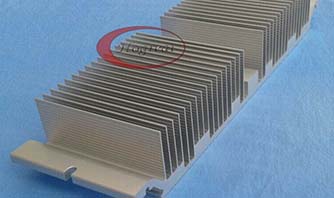

Aluminum Extrusion Led Heat Sink

Assuming that all materials are one cubic centimeter in size, the weight of copper is 8.9 grams, let it rise 1K, it needs 3.4KJ of heat, the weight of aluminum in this size is 2.7 grams, let it rise 1K, the heat required is 2.4KJ, That is to say, per unit volume, the heat capacity of aluminum is only 70% of copper, and it dissipates heat faster.

Therefore, although the thermal conductivity of copper is higher than that of aluminum, the transfer resistance of heat from the CPU to the environment is small, but its thermal capacity is greater under the same volume, and the temperature rise is slow, so the temperature gradient is small, and the overall heat transfer capacity is not Not necessarily much better than aluminum.

In thermodynamics, the heat transfer rate equation is Q=KAΔt, where Q is the heat transferred, K is the thermal conductivity of the material, A is the heat transfer area, and Δt is the temperature difference. Under the same volume, it is assumed that A is the same, Q It is mainly determined by the temperature difference between the thermal conductivity of the material and the heat transfer medium. The heat dissipation of the CPU is actually two processes, one is from the CPU to the heat sink, and the other is from the heat sink to the environment (air). For pure copper heat sinks, the heat from the CPU to the heat sink, because K is larger, Δt is also larger (the temperature difference between the heat sink and the CPU, because the copper temperature rises slowly at the same volume), the heat transfer rate in this process is obvious Better than a pure aluminum radiator, but in the second stage, when the heat is transferred from the radiator to the air, K is the same (all air), Δt is the pure copper radiator is smaller (here is the radiator and air Temperature difference), in this process, the efficiency of the pure copper radiator is lower than the aluminum radiator. There has always been a saying that copper absorbs heat quickly and aluminum dissipates heat quickly, which still makes sense.

Pure copper radiators are not unprecedented. Pure copper Ultra 120E, which weighs 1.89kg, while ordinary Ultra 120E radiator is only 785g, which weighs 1.1kg, but what about performance? as follows:

Under the premise of such high cost and heavyweight, the performance gains brought by pure copper heat sinks are actually very low, and they are only 4 degrees lower than ordinary aluminum heat sinks. Of course, if you pursue the ultimate, it is not bad. , But the price is too high.

In general, pure copper heat sinks are not cost-effective, the cost is too high, the processing is more difficult, the cost performance is low, the eyeballs are acceptable, and it certainly cannot become the mainstream, and the aluminum extrusion LED heat sink. It has been the protagonist for so many years and is the result of the correct choice. For example, it is cheap, low in density, easy to form, and has a good hardness. It is also very important. The heat sink made by it is very close to pure copper.

In addition:

The copper radiator has the following problems

1. Too expensive

2. Too heavy

3. The surface is easily oxidized.