LED (Light Emitting Diode) is a solid-state light source. The application of LED has a long history. In the past, it was mainly used in the indicators of various electronic devices, large screen displays, signal lights, and LCD screen backlight sources. In recent years, with the progress of crystalline growth process technology and nanotechnology of GaP and GaN-based III-V compound semiconductors, the light efficiency and high-power integration technology of LEDs have been greatly improved. LEDs have begun to be used in the lighting field. There are many kinds of lighting fixtures with high-power LEDs, such as LED street lights, LED mining lights, LED emergency lights, LED car lights, and LED landscape lights.

The light-emitting principle of LED is solid-state light emission. According to the principle of solid-state light-emitting physics, the spectrum of LED is almost concentrated in the visible light band, so the luminous efficiency is as high as 90% or more. Therefore, LED is hailed as a new light source in the 21st century and will soon become an incandescent lamp and a fluorescent lamp. The fourth generation of light sources after high-intensity gas discharge lamps is recognized as one of the top ten current cutting-edge technologies. LED light sources, such as new lighting sources, will surely replace traditional lighting sources and are driving a new industrial revolution- -Lighting revolution.

Custom led heat sink supplier china believes that heat dissipation is a key issue for LED street lights. LED is a cold light source, and does not generate hot high temperatures like incandescent lamps. However, the LED itself has poor temperature resistance, so the heat generated during the operation of the light-emitting tube must be effectively dissipated into the air to ensure that the chip works at a safe temperature In this environment, the LED lamp can truly reflect the advantages of long life.

LED dies and coated phosphors are produced under high temperature conditions of several hundred degrees, and they have a certain temperature resistance. However, there is a thermal resistance between the housing and the die of the LED. This thermal resistance causes a temperature difference between the housing and the die when the LED is used, and the temperature of the die will be higher than the temperature of the housing.

Due to advances in the production technology of light-emitting tubes, the thermal resistance inside high-power light-emitting tubes is getting lower and lower. At present, the thermal resistance of 1-watt light-emitting tubes is generally below 15 degrees / watt, that is, 1 for 1-watt light-emitting tubes. The electrical power of the watt is only 15 degrees higher than the temperature of the tube case. According to the current temperature resistance level of the tube material of the light-emitting tube, the tube temperature can work safely for a long time if the temperature of the tube core does not exceed 150 degrees. In this way, it can be used safely when the case temperature is 135 degrees. However, due to the limitation of the shell packaging material, the temperature of the shell in actual use should preferably not exceed 70 degrees, so that the die temperature is only 85 degrees, and the transparent packaging material of the light-emitting tube will not age quickly. No problem in long-term stable work. Therefore, it is not necessary to lower the temperature of the semiconductor lamp during operation, but it is necessary to reduce the thermal resistance between the light-emitting tube housing and the lamp body housing, so that it can produce stable work with a relatively small volume and a relatively low cost. Semiconductor lights.

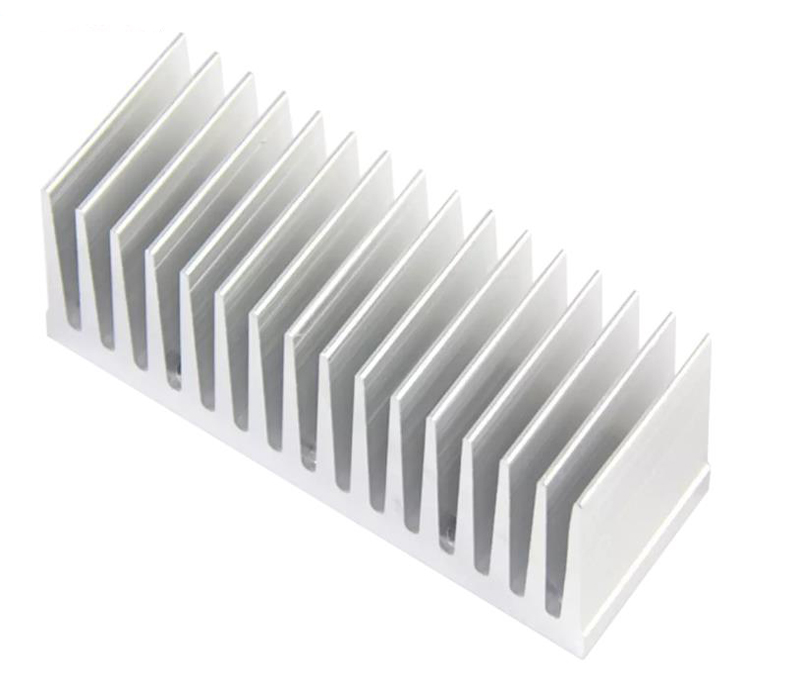

To effectively dissipate heat, reduce the volume and production cost of the lamp, the lamp body must have a reasonable custom led heat sink.

Custom Led Heat Sink

c. Selection of heat-dissipating materials: In order to make good LED street lights, we first select heat-dissipating materials. Currently, the heat sinks are basically metal materials, which are mainly due to three considerations:

①Good thermal conductivity——Compared with other solid materials, metal has better thermal conductivity;

② Easy to process-good ductility, relatively stable high temperature, can use various processing techniques;

③Easy to obtain—Although metals are also non-renewable resources, they have a large supply, do not require special processes, and the price is relatively low. Based on this, the types of materials used for heat sinks have been determined, and the specific types must be determined based on this. The following table shows the thermal conductivity of conventional heat sink materials and common metal materials.

Naturally, the higher the thermal conductivity, the better, but at the same time, it is necessary to take into account the mechanical properties and price of the material. Gold and silver with high thermal conductivity cannot be widely used because of their soft texture, too high density, and too expensive; iron has low thermal conductivity and cannot meet the performance requirements of high heat density occasions, so it is not suitable for high performance. heat sink. The thermal conductivity of copper is also very high, which can be hindered by the disadvantages of insufficient hardness, higher density, slightly higher cost, and difficulty in processing, so it is less used in heat sinks. As the highest content metal in the earth's crust, aluminum is favored because of its high thermal conductivity, low density, and low price. However, due to the low hardness of pure aluminum, it is usually mixed with various formulation materials to make aluminum alloys in various applications. The industrial extrusion aluminum heat sink obtains many characteristics that pure aluminum does not have, making it an ideal choice for heat sink processing materials.